New Delhi: The Union Cabinet, chaired by Prime Minister Narendra Modi, has approved four new semiconductor manufacturing projects under the India Semiconductor Mission (ISM), with a total investment of ₹4,594 crore. The decision marks a significant leap in India’s push towards compound semiconductors and advanced packaging technologies.

The projects — led by SiCSem, Continental Device India Pvt. Ltd. (CDIL), 3D Glass Solutions Inc., and Advanced System in Package (ASIP) Technologies — are expected to create 2,034 direct skilled jobs and spur large-scale indirect employment across India’s electronics manufacturing value chain.

With these approvals, ISM now has 10 sanctioned projects across six states, attracting investments of approximately ₹1.6 lakh crore.

read also: PM Modi Responds to Trump’s 50% Tariff Hike: “India Will Not Compromise on Farmers’ Interests”

State-Wise Project Details

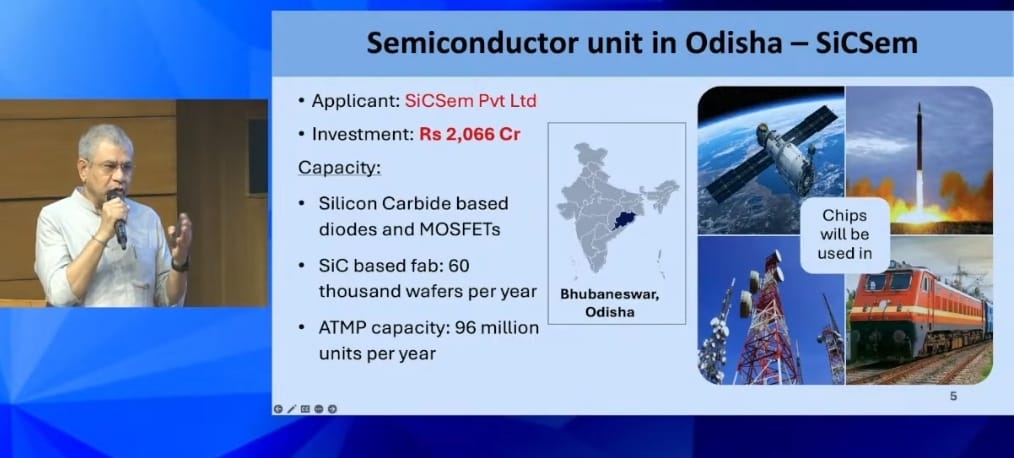

Odisha

SiCSem (with UK’s Clas-SiC Wafer Fab Ltd.): Setting up India’s first Silicon Carbide (SiC) compound semiconductor fab at Info Valley, Bhubaneswar.

Capacity: 60,000 wafers/year & 96 million packaged units/year.

Applications: Defence, electric vehicles, railways, solar inverters, data centres.

Investment: ₹2,066 crore.

3D Glass Solutions Inc.: Establishing an advanced packaging and embedded glass substrate unit, bringing 3D Heterogeneous Integration (3DHI) technology to India.

Capacity: 69,600 glass panel substrates/year, 50 million ATMP units/year, and ~13,000 3DHI modules/year.

Investment: ₹1,943 crore.

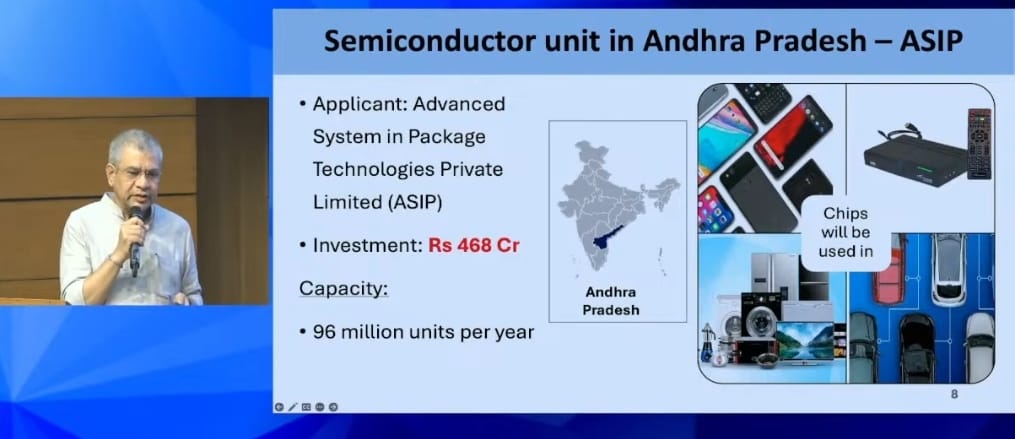

Andhra Pradesh

ASIP Technologies (with South Korea’s APACT Co. Ltd.): Building a 96 million units/year semiconductor packaging facility for mobile, automotive, and consumer electronics.

Investment: ₹468 crore.

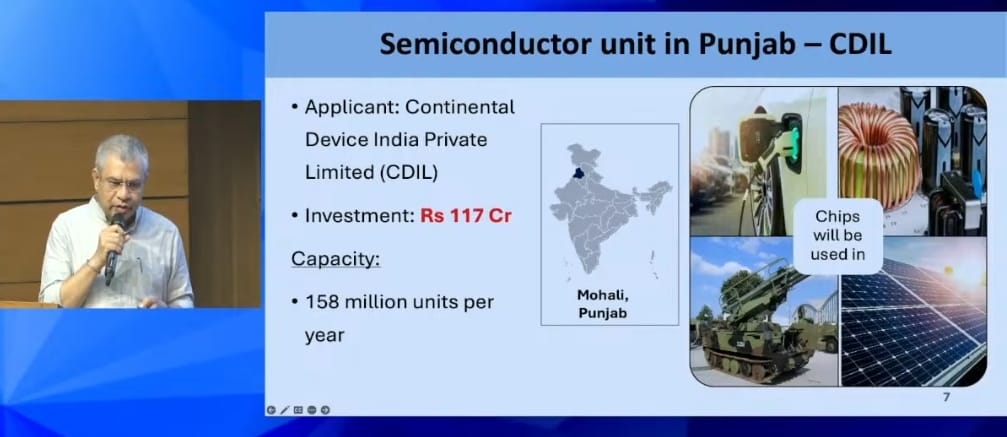

Punjab

CDIL: Expanding Mohali plant to produce high-power discrete devices (MOSFETs, IGBTs, diodes).

Capacity: 158.38 million units/year for automotive, renewable energy, and industrial uses.

Investment: ₹117 crore.

India’s Semiconductor Roadmap

Launched in 2022, the Semicon India Programme aims to build a complete domestic semiconductor ecosystem — from design and wafer fabrication to packaging, assembly, testing, and large-scale production. Six projects are already under construction, with a combined capacity to produce 24 billion chips annually.

Union Minister Ashwini Vaishnaw hailed the new approvals as a milestone, noting,

“These include the country’s first commercial compound fab and a world-class advanced glass-based substrate facility. They will significantly contribute to making India self-reliant in semiconductors.”

The Minister said that The ISM has already attracted major investments and fostered a growing design ecosystem, with 72 Startups and 278 academic institutions engaged in semiconductor R&D and training. Over 60000 students are benefitting from semiconductor talent development programmes across the Country. He added that These Projects will accelerate our journey towards Atmanirbhar Bharat in Electronics manufacturing and create a talent pool that will serve global Industry.

The minister also confirmed that SEMICON India 2025 will be held from September 2 at Yashobhoomi, with Singapore, Japan, Malaysia, and South Korea as partner nations.

Since 2014, electronics manufacturing in India has grown sixfold to ₹12 lakh crore, while exports have surged eightfold.

- Electronics exports 8 times growth Rs. 3.3 Lakh Crore

- Mobile Manufacturing units from 2 to 300+ today

- Mobile Phone production 28 times growth Rs. 5.5 Lakh Crore

- Mobile Phone Export 127 times growth Rs. 2 Lakh Crore