New Delhi: India’s defence and aerospace sector has long recognised that engines are the “heart” of fighter aircraft and a key determinant of strategic independence.

Society of Indian Defence Manufacturers (SIDM), in its recent report titled “A Road Map for Aero Engine Development in India”, warns that India remains vulnerable because of heavy dependence on foreign-supplied jet propulsion systems.

For example, the indigenous Kaveri programme—intended to power the Tejas Mk‑1 light combat aircraft—did not meet performance goals and was eventually shelved.

Read Also: From Importer to Global Exporter: Armenia Chooses India’s Su-30MKI Deal Over Russian & Western Jets

With future combat jets like the Advanced Medium Combat Aircraft (AMCA) in development, the demand for high-thrust engines is set to surge, compelling India to act.

What is “Mission Aero Engine”?

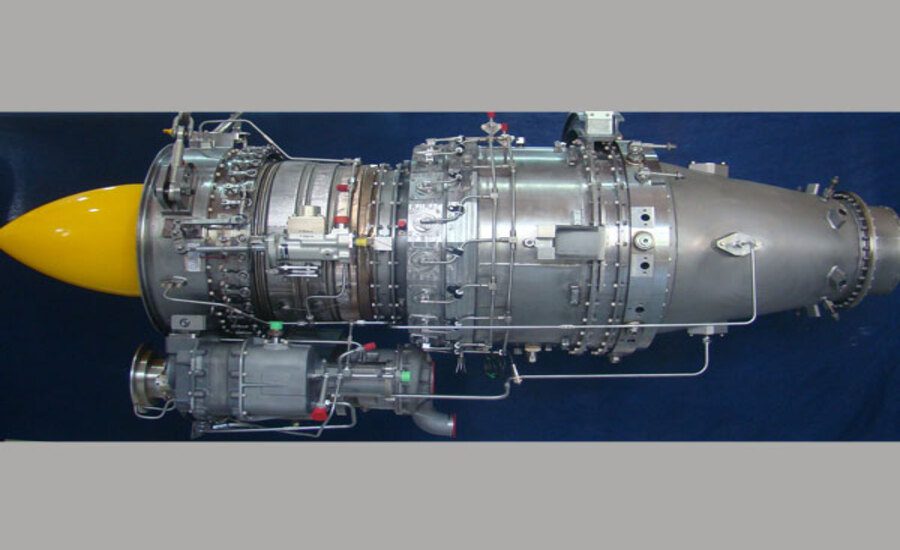

The proposal seeks to launch a national-level initiative — dubbed Mission Aero Engine — with the goal of designing and manufacturing an indigenous 110 kN thrust-class jet engine. This engine is intended both for military fighter aircraft and modified variants for civil aviation use.

Key components of the mission include:

- Government-industry coordination under the “Atmanirbhar Bharat” framework.

- Policy incentives and targeted funding to build the engine ecosystem.

- Leveraging existing institutions such as the Gas Turbine Research Establishment (GTRE) and encouraging the private sector to participate.

- The core engine for fighter jets, and with modifications (e.g., thrust reversers, additional fan/turbine stages) adapted for single-aisle commercial aircraft like the A320 or Boeing 737.

Mission Aero Engine: Key Figures & Market Potential

→ SIDM estimates that over the next decade, India will need at least 712 engines for aircraft such as Tejas Mk-1/Mk-1A/Mk-2 and AMCA.

→ The value of this market is estimated at over ₹60,000 crore (~$7–8 billion) in the coming years, making it a major industrial opportunity.

→ The recently reported figure of about 1,100 engines over the next decade puts even higher demand pressure.

Strategic Context: Why India cannot wait

→ Over-reliance on foreign engine suppliers (USA, France, UK, Russia) means India remains vulnerable to sanctions or supply-chain disruptions.

→ Developing an indigenous engine strengthens India’s strategic autonomy in aerospace and defence.

→ The co-development talks with Safran (France) for next-gen fighter engines reinforce that India is pursuing multiple paths.

Mission Aero Engine: Challenges & The Road Ahead

While mission framing is bold, major challenges remain:

- India lacks high-altitude wind-tunnel testing facilities and flight-test bed infrastructure essential for high-thrust jet engine certification.

- Past engine programmes like Kaveri faced technology-denial, funding constraints, material/manufacturing gaps and timeline delays.

- Building a full industrial supply chain, ensuring quality manufacturing, and sustaining long-term upgrades require strong policy and private-sector engagement.

However, with a mission mode push, integrating institutional cooperation, fresh funding, and private-sector entry, the initiative could mark a turning point.

Importance of Mission Aero Engine for India’s Aerospace Future

→ If successfully executed, India would move from being a major importer of high-thrust jet engines to being a designer/manufacturer/exporter.

→ The dual-use architecture (military + civilian) allows economies of scale and boosts the domestic supply chain for both defence and civil aviation markets.

→ A robust domestic engine-manufacturing ecosystem would spur new jobs, industrial clusters, and help India’s Make-in-India vision in aerospace.

→ India’s fighter-fleet modernisation programmes (Tejas variants, AMCA) would become less vulnerable to foreign restrictions.