Located to the north-west of the Moradabad district in UP, near the river Ganges, lies a small, quaint town named Amroha, also known as the hub of manufacturing Dholaks and Tablas. While its neighbors such as Sambhal, Rampur, and Bijnor are known for their thriving glasswork industries, Amroha also holds a surprising secret: a hidden pool of skilled glassblowers.

Despite having talented artisans, Amroha lacked the entrepreneurial spirit to turn their craft into a booming business. The town’s workers often migrated to nearby districts like Firozabad to find work. Meanwhile, its neighbors flourished with glass businesses, exporting exquisite handicrafts.

As the demand of the public and industries shifted from raw glass to tougher, more durable options, Amroha’s artisans, though skilled, missed out on this crucial shift.

Glassworkers in Amroha were leaving for jobs in other cities, even though there were businesses nearby that needed them. To address this, the government set up a special glass factory in Amroha under a program to boost exports in Uttar Pradesh. This factory not only created jobs in Amroha and helped businesses there export more glass products, but it also brought down the cost of making glass items in nearby districts.

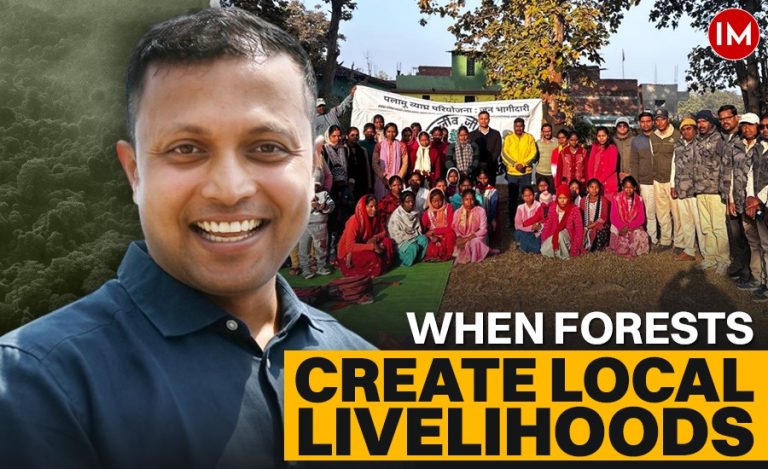

The Amroha Glass Factory, a special facility to help businesses, was opened in 2020 after the first wave of COVID-19. This was thanks to the efforts of the district magistrate at the time, Mr. Umesh Mishra, IAS. The factory was a big help for many people who lost their jobs in other cities during the lockdown. Currently, it’s running smoothly under the leadership of the current district magistrate, IAS officer Rajesh Kumar Tyagi.

In a recent interview with Indian Masterminds, Mr. Tyagi highlighted the improvements brought by the glass factory. He said, “Traditionally, glasswork was done by hand, which posed a high risk of injuries. Additionally, the finished products often lacked a polished look, making them unappealing to buyers. The advanced technology at the factory has addressed these issues. Now we can produce high-quality glass items safely and efficiently, ensuring they meet international standards and customer expectations.”

COMMON FACILITY CENTER

The government, along with the District Industries Promotion and Entrepreneurship Development Centre, set up a special facility called the Common Facility Centre (CFC) to help glass businesses in Amroha. This one-stop shop has everything a glass maker needs, from machines for cutting glass to special furnaces that make it extra strong (toughened glass). Worker safety is also a priority in the factory, with built-in safeguards.

The CFC offers a wide range of services for glass businesses and handicraft units, including:

Laser cutting for precise shaping, finishing touches for a polished look, water jet cutting for intricate designs, laser engraving for personalized items, sandblasting for textured effects, lamination to bond multiple glass pieces, insulation for temperature control, coloring the glass for a unique touch, sample making using furnaces to test designs.

This comprehensive service helps businesses create high-quality glass products efficiently.

IMPACT

The General Manager of the Glass Factory in Amroha, Mr. Avnish Agarwal told Indian Masterminds, “The glass factory has been established to spread the technical knowledge involved in the glass industry to entrepreneurs and exporters around the district. This has quickened the state’s industrial development.”

The total cost of the project amounts to 1299.98 lakh rupees. The Uttar Pradesh government has provided a margin money subsidy of 909.98 lakh rupees for this project. The scheme is expected to create direct and indirect employment opportunities for 2500 people.

The establishment of this plant is expected to boost the glass export sector by 25%. It has also reduced the region’s dependence on the Firozabad district by promoting local labor and reducing migration through job creation, within the district. Additionally, production cost in the region is expected to decrease.

Mr. Agarwal highlights that previously, most glassworks were done manually, resulting in slow production rates. This project aims to increase production capacity by utilizing automatic machines, streamlining the process, and benefiting entrepreneurs and exporters.