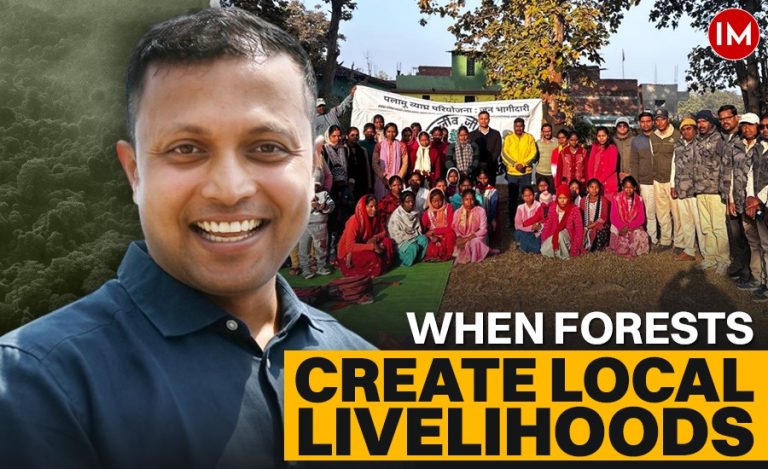

As plantation drives are conducted across the country in the beginning of every monsoon season to regenerate greenery in degraded forest areas, they also leave behind lot of plastic wastes in the form of poly-pot bags that are used in the plant saplings. These bags cause adverse effects on the ecosystem and environment. But, now, thanks to trainee IFS officer, Mr Anupam Sharma (SDO Satna forest division) and his wife Mrs Bhavna Sharma (an expert on solid waste management), the Satna district of Madhya Pradesh is about to become free of such bags because of the couple’s plastic-free plantation drives. In an interaction with Indian Masterminds, Mr. Sharma talked about this plastic-free initiative and revealed how they implemented effective waste management.

TOWARDS PLASTIC FREE ENVIRONMENT

Plantation is one of the main activities of the forest department, and in the year 2021, around 3 crores saplings were planted in Madhya Pradesh. Around 4.5 lakhs saplings were planted in Maihar subdivision in 5 hectares of degraded land in the months of June-July. “During one of my inspection visit, my wife turned my attention towards these black poly-pot bags that were not removed from the site after plantation.” Maihar subdivision contains Maihar, Amarpatan and Mukundpur forest ranges of Satna forest division. There were around 11 to 12 sites where these plantation drives were conducted. So, it was a matter of around 4,900 kgs of plastic waste management. This set the officer thinking: “Now the question was, how to remove and utilize this plastic waste in an environmentally friendly manner at minimum cost?”.

BRAINSTORMING ON WASTE MANAGEMENT

Usually these kinds of poly-pot bags are made up of LDPE (low density polyethylene) that can be recycled and reused. Normally, it is burnt or dumped in a landfill, which are not good options. The couple brainstormed on 3 to 4 ideas including In-Situ processing and recycling of plastic waste into granules and briquettes. This technique requires a hefty amount of money for installation of machinery in the initial level, so this couldn’t be considered. Second, they thought of some cement factories where this could be utilized as combustible raw material, but they didn’t show any interest. They also went to Maihar Municipal Corporation, but they were allowed to just dump it in a landfill. Since there is no incineration plant in Satna, this option was also of no use. Finally, they decided to call some scrap dealers who can carry this plastic waste to processing sites in Jabalpur and Indore.

EARNINGS FROM PLASTIC WASTE

Mr. Sharma found a scrap dealer who agreed to buy this plastic waste at the rate of Rs 11-12 per kg. “Our first objective of removing this waste from sites was fulfilled like this. Not only our team, but JFMC and locals also contributed to collecting and carrying this waste to the collection point. We collected around Rs 59,000 by this sale,” Mr. Sharma informed. JFMCs are Joint Forest Management Committees of villages surrounding the plantation areas. The collection of waste, dealing, and procurement were all done in just two months.

PROPER UTILISATION OF MONEY

“By effective utilization of this money, we wanted to give a concrete message that something unproductive can be turned into productive,” Mr. Sharma says. After a mutual discussion between the forest department and JFMC, they arrived at the decision to start some experimental initiatives.

BIO-METHANATION PLANT

This plant was installed at Maa Sharda Devi Temple Management Committee’s Old Age Home with the capacity to process 5kg waste per day, generating 450gm gas a day by using flowers and garlands offered to the deity, which, otherwise, used to rot on the ground under human feet or in landfills.

OIL EXPELLER MACHINE

An oil expeller machine that can process 4-8 kgs of oil seeds per hour was handed over to Bareh Bada village JFMC after training the locals in machine operation. By using it, one can extract oil from oil seeds like mustard, groundnut, linseed, sesame, mahua, neem, karanj etc.

MASALA & HERBS GRINDER

A masala grinder machine was handed over to Tala Village JFMC with a capacity to grind 500gm masala at a time. It is useful to grind spices like cloves, chili, turmeric, coriander and even Ayurvedic herbs.

MENSTRUAL HYGIENE AWARENESS

“With the leftover amount of money, we conducted a couple of sessions with the help of JFMCs, to spread awareness among women about menstrual hygiene and health, where we also distributed around 500 sanitary pads”, informed Mr. Sharma.

PREVENTED CARBON EMISSION

Increasing level of CO2 (carbon dioxide) is the main factor of global warming. “We could prevent the emission of around 30,000 kgs of carbon into our environment that would have been generated by 4,900 kgs of plastic waste. In ths way, we made right use of the money earned from plastic waste,” the officer informed.

Mr. Anupam Sharma is a 2018-batch IFS officer who had graduated from IIT Delhi. On why he chose Forest Service, he said, “This service provides an opportunity to connect with the most underprivileged segments of society – tribal and forest dependent communities. I want to work actively for them.”