New Delhi/ Bangalore: India has long sought to reduce its dependence on foreign suppliers for key missile technologies and propulsion systems. Under the national “Atmanirbhar Bharat Mission” push, private-sector firms are increasingly entering domains previously dominated by state-run companies.

What’s New: Prime Toolings Dual Boosters & Rotating Detonation Engine

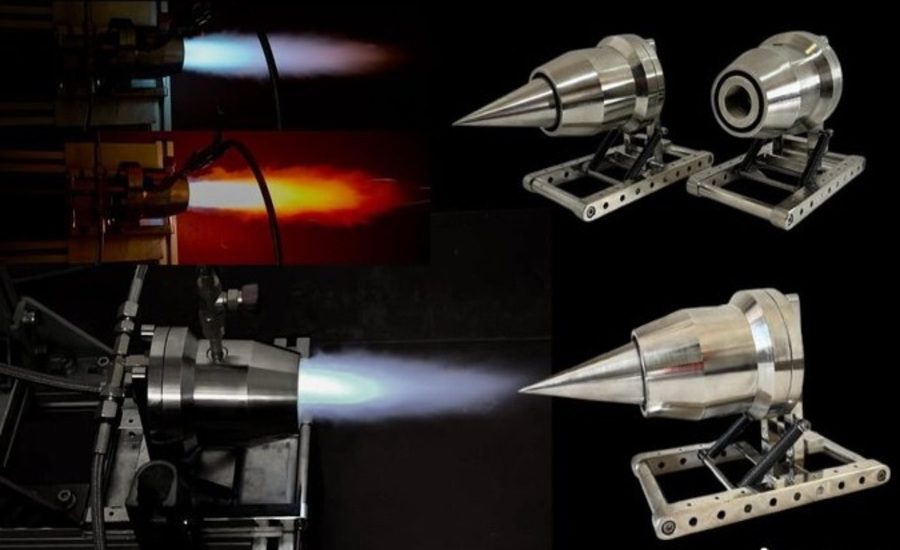

Bengaluru-based Prime Toolings has revealed that it is developing dual-booster engines to work in tandem with its earlier announced rotating detonation engine (RDE) programme.

Prime Toolings Dual-booster system

The dual-booster configuration is being designed to increase missile thrust and altitude gain, thereby extending operational range and payload delivery efficiency.

It marks a modular design approach, suited to different missile classes — tactical, strategic or air-defence.

According to sources, integration is planned with a variant of the Barak missile (developed by India & Israel) by February 2026, which means practical deployment in less than a year.

Rotating Detonation Engine (RDE)

Prime Toolings had earlier unveiled a prototype RDE — a propulsion system using continuous detonation waves, promising up to ~25 % improvement in fuel efficiency over conventional designs.

Read Also: From Russia with Pride: India’s AK-203 Sher Rifle Becomes 100% Made-in-India by December 2025

The RDE is in the thrust class of 1-12 kN, targeting short-range tactical missiles with ranges of 300-500 km.

Strategic Significance of Prime Toolings Dual Boosters for India

The dual-booster plus RDE architecture signals that India is moving beyond conventional propulsion methods (solid or liquid motors) towards next-gen modular propulsion systems.

By extending missile range and flexibility, this development enhances India’s strike and interception capabilities, crucial in regional security contexts.

From a manufacturing perspective, this underscores the growing role of private sector firms like Prime Toolings in defence and aerospace – a key element of Atmanirbhar Bharat.

The modularity of the booster system means that India could adapt the propulsion stack across multiple missile types rather than bespoke systems for each platform.

Why this matters now

The timeframe (test planned February 2026) means that this is not speculative far-off technology — it is active development.

Regionally, this comes at a time when India is enhancing air-defence and strike capabilities across land, sea and air domains.

For the Indian defence industrial base, this is a demonstration of capability shift: private firms now undertaking propulsion systems development.

Export potential: A modular dual-booster/RDE propulsion system could become part of India’s defence exports in coming years, boosting defence manufacturing revenues.

Key Challenges & What to Watch

Scale-up: Moving from prototype to full-scale test is complex, especially for propulsion systems subject to intense thermal, mechanical and systemic stresses.

Certification: For strategic missiles, rigorous testing cycles, reliability and safety standards apply — delays or setbacks are common.

Integration: Integrating with missile systems (like Barak variant) involves avionics, control systems, supply-chain coordination and thermal management.

Export & geopolitics: If successful, India will need to navigate international export controls, technology transfer rules and regional responses.

Read Also: HAL CATS Warrior Manned-Unmanned Teaming Revolution: 2027 Flight to Transform Indian Air Power